Protect Air, Surfaces, and Hands with TRIFECTA OF Building WELLNESS

Since

2016

bioPURE® Innovative Solutions

Do you want a healthier environment

where you live, work, and play?

At bioPURE, we are passionate about our mission to provide innovative solutions for healthier environments to where you live, work, and play. This is driven by our innovative solutions that are effective and safe. We are changing the standard when it comes to proactive germ control and what it means to truly have a healthy environment. bioPURE’s technology is based on tried-and-true science that has been used for years in many industries such as health care, agriculture, food processing, and automotive. We have taken this science and applied it to the home and business environments, creating solutions that are safe for use around kids and pets. Our solutions are backed by third-party testing, so you can be confident in their efficacy. When you use bioPURE services, you are taking a proactive step to improve the health of your environment.

bioPURE® Healthier Environment Services

Commercial Disinfection

bioPURE professional disinfection treatments are the most effective way to ensure your business is well protected from pathogens.

Residential Disinfection

bioPURE professional sanitizing and disinfecting service uses EPA-registered hospital type products and electrostatic applications to treat your home.

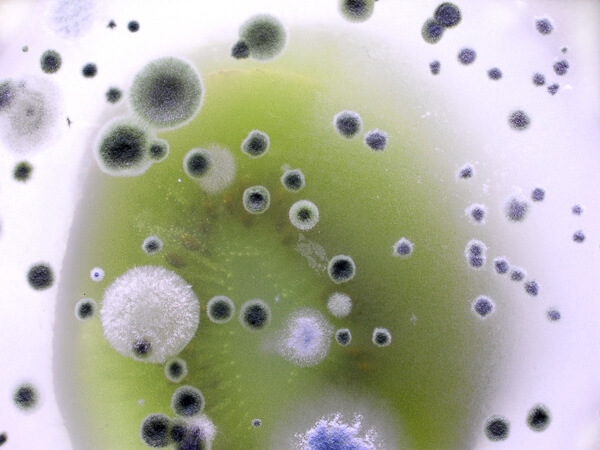

Mold Remediation

bioPURE professional mold removal and remediation experts work diligently to rid your home or office of all traces of mold.

Indoor Air Quality

bioPURE professional indoor air quality service to test your air and identify any pollutants or contaminants.

Crawl Space Services

bioPURE professional crawl space encapsulation and restoration services to help protect your home from damage.

Water Mitigation

bioPURE professional water damage restoration to help restore your home to its original condition.

Contact bioPURE® today to learn more about our products and services and how we can help you create a healthier environment… where you live, where you work, where you play.

Why bioPURE®?

- Making environments healthier since 2016

- Free Estimates and Consultations

- Professional Service

- Fast Response Time

- High Customer Satisfaction

- Certified, Licensed & Insured

- Residential and Commercial Service

- Safe EPA Approved Treatment Solutions

How bioPURE® Can Help Your Home or Business

Safe and Effective Solutions

bioPURE is dedicated to creating healthier environments for homes and businesses. We offer a full range of services and products to help you create a space that is free of harmful chemicals and pollutants. Our team of experts are available to assess your needs and recommend the best solutions for your space. bioPURE is committed to helping you create a safe and healthy environment for your family, employees, and clients.

WHAT CLIENTS SAY

Industries We Serve

Home

Kitchen, Living Room

Kids Play Area, Bath

Veterinary

Kennels, Groomers,

Animal Hospitals

Healthcare

Hospitals, Dr. Office,

Nursing Care Facilities

Schools

Daycare, K-12,

University

Office & Commercial

Surfaces, Elevators,

Restrooms, Lobby's

Food & Beverage

Restaurants, Cafeterias,

Catering, Distillery

Government & Military

Offices, Municipal, Prisons,

Bases, State Parks

Fitness

Gym, Yoga Studios,

MMA, Trampoline Parks

Sports

Stadiums, Arenas,

Training Facilities

Agriculture

Poultry, Livestock,

Processing, Feed & Grain

Events & Conventions

Fairs, Music Venues,

Convention Centers

Hospitality

Hotels, Air BnB,

Vacation Rentals

Travel

Airlines,

Cruise Lines

Transportation

Buses, Cabs,

Subways, Trains

Retail

Stores, Malls,

Movie Theater

Contact your local bioPURE® for a free consultation.

The bioPURE® Difference

- Pursuing Greater

- Uncommonly Dependable

- Relentlessly Serving

- Educating to Empower

Trust us for a healthier environment…

Where you live, Where you work, Where you play.